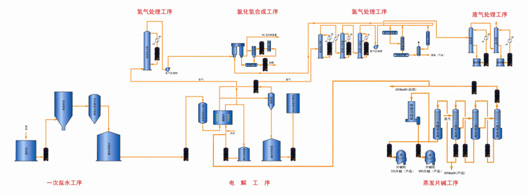

Caustic Soda

Primary saltwater process:

Raw salt goes into salt dissolver, light salt water from electrolysis process, the saturated raw brine was prepared by dissolving recycled water and supplementary water.

The electrolysis process:

Electrolysis process includes three parts: secondary brine refining, electrolysis and dechlorination of light brine.

The evaporation and caustic soda solid process:

32% NaOH from elctrolysis process, after three-effect countercurrent falling film evaporation, to increase the NaOH concentration in the lye to 50%, it is sent to the concentration unit to produce sheet and granular alkali.

Chlorine gas process:

The wet chlorine from the electrolysis process is first washed by the chlorine washing tower, enter the chlorine cooler to cool with chilled water. Through the water mist separator it is sent to the packed column to contact with the countercurrent of sulfuric acid for the first step of dehydration, chlorine gas from the packed column is then sent to the bubble-cap tower for countercurrent contact with concentrated sulfuric acid for further dehydration, and then after the acid fog trap capture acid fog and then through the chlorine gas compressor compressed and pressurized and send to chlorine gas users.

Waste gas treatment process:

When the device is on and off and in accident condition, chlorine gas is first absorbed from the lye in the circulating tank inside the absorption tower, after the absorption reaction the tail gas reenters the tail gas tower and is further absorbed by lye, at the same time, 10%Nac10 product is made from the absorption liquid and sent to the acetylene device.

Hydrogen treatment process:

The wet hydrogen from the electrolysis process, with a temperature of about 85C, enters the lower part of the hydrogen washing tower, and directly cools and washes with the circulating liquid sprayed in the tower, the alkali fog and condensed water contained in the hydrogen are carried away by the circulating liquid, then it is pressurized by hydrogen compressor and sent out of the boundary zone after two stages of cooling.

Hydrogen chloride synthesis and high purity hydrochloric acid process:

Chlorine and hydrogen are burned in a two-in-one graphite synthesis furnace,becomes chlorine and hydrogen gas. The generated hydrogen chloride gas is cooled by hydrogen chloride cooling water tank and hydrogen chloride cooler and then partly sent to VCM device for raw material and high purity hydrochloric acid absorption system by hydrogen chloride distribution platform.