More introduction

THT heat exchange equipment as the main equipment of ship’s cooling system such as oil cooler, fresh water cooler, central cooler, diesel engine cooler, jacket water cooler etc. they are widely used in oil tankers, liquefied natural gas ship, container ship, bulk carriers and engineering ships, they play an important role in the navigation of ships. The operating conditions of seawater with high corrosion and easy scaling test the corrosion resistance and high performance of THT heat exchanger equipment, and the safety and stability are tested by the continuous operation for a long time.

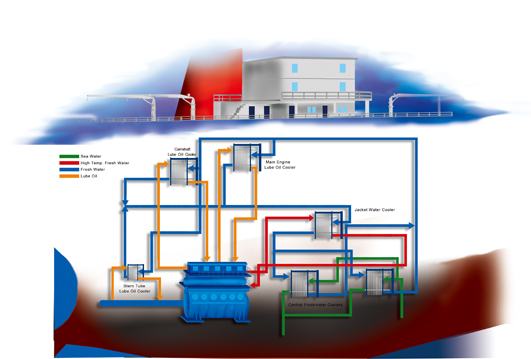

Marine cooling water system usually includes open seawater system, closed fresh water cooling system, central cooling system. The pipelines of seawater and freshwater cooling in central cooling system are separated, which means there is only one or two bigger plate heat exchanger equipped with titanium plates. Titanium is the only material that can withstand the aggressive seawater without corrosion damages on the plates in the heat exchanger. This means that the central cooler can operate without problems using seawater as the cooling media for the internal freshwater cooling system.

Flow Diagram

The advantage of central cooling system is that the use of corrosive seawater is limited to one or two plate heat exchangers, and thereby the use of exotic material for the plate heat exchanger and the seawater pipeline is limited to a minimum. The rest of the plate heat exchangers are normally equipped with stainless steel plates there is no corrosion risk as the heat exchangers work in freshwater.

Central cooling system divided into high temperature hot freshwater and low temperature warm freshwater closed system. The former is used for cooling the main engine and the latter for cooling the hot freshwater and various coolers. The heated warm freshwater is cooled by the open seawater cooling system in a central cooler. Therefore, only one cooler with seawater as coolant is used, which simplifies the layout of seawater piping system.