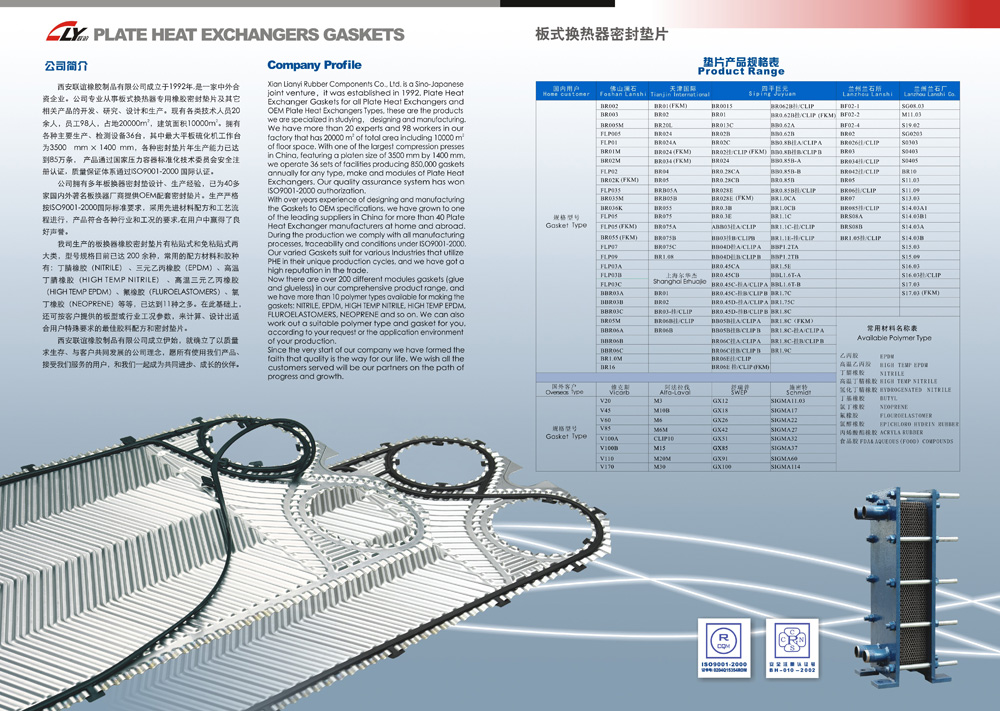

More introduction

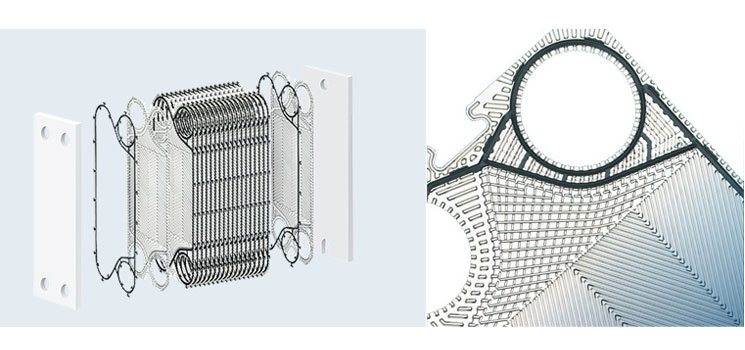

Plate heat exchangers offer better economy maximum efficiency and easy maintenance.

The gasketed plate heat exchanger is widely recognized today as the most economical and energy efficient type of heat exchanger on the market. With its low cost, flexibility, easy maintenance, and high thermal efficiency it is unmatched by any type of heat exchangers.

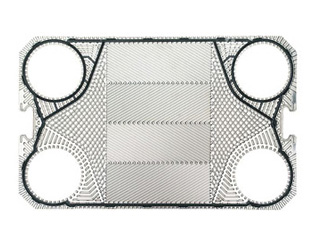

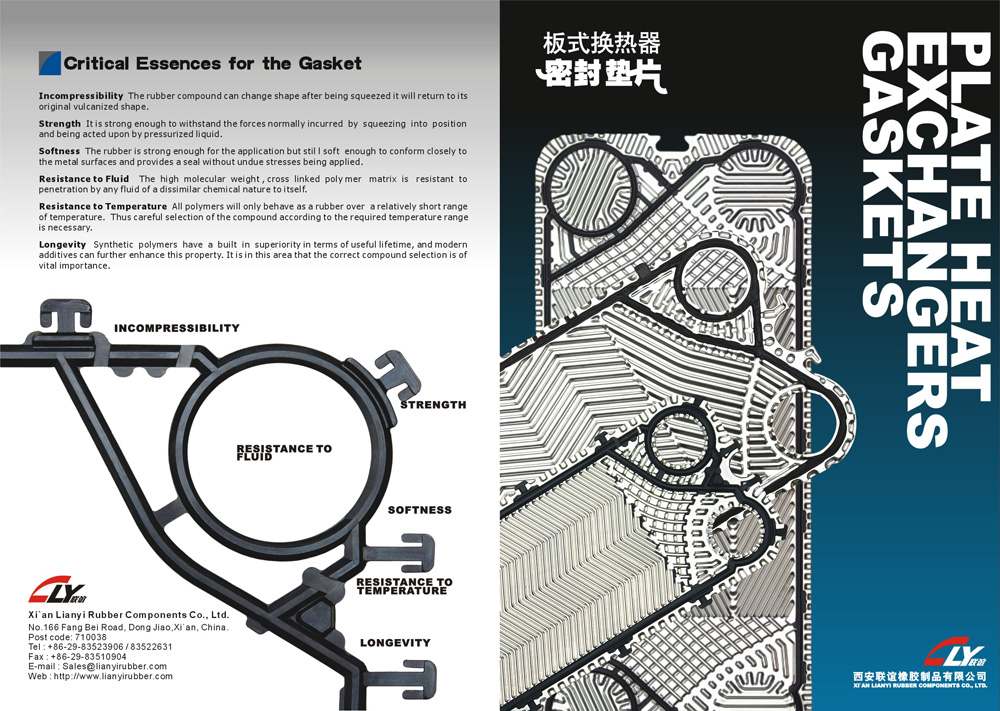

The key to plate heat exchanger's efficiency lies in it's plates and rubber sealing gaskets.

Each heat transfer plate is fitted with a rubber gasket partly to seal and partly to distribute the process fluids. With corrugation patterns in the plate that induce turbulent flow, it not only achieves unmatched efficiency it also creates a self-cleaning effect thereby reducing fouling. The plate corrugations are available in different pressing depths and patterns depending on the application. All are designed to achieve turbulence across the entire heat transfer area in order to get the highest possible heat transfer coefficients with the lowest possible pressure drop and allow for close temperature approaches. Consequently this means smaller heat transfer area, smaller heat exchangers and sometimes even less heat exchangers. This again means less space requirements, reduced secondary flow rates and smaller pumps.

As the excellent properties and advantages, plate heat exchangers are almost widely used in all industries.

The major relevant industries as: OIL, MINING, FOOD MANUFACTURING, PHARMACEUTICALS, THERMAL HEAT AND COOLING INDUSTRIAL, DAIRY PROCESSING, WINE AND BEVERAGE, PETROCHEMICAL, OFF-SHORE POWER, BREWING, and so on.