More introduction

The detachable plate heat exchanger belongs to the dividing wall type heat exchanger, it has high heat transfer efficiency, small resistance loss, compact construction, sensitive temperature control, easy change of required capacity, convenient mounting and dismounting, long working life etc, is the most advanced energy-saving heat transfer equipment at present. Plate heat exchanger is mainly used for heating, cooling, evaporation, condensation, sterilization and disinfection, heat recovery and other occasions.

THT plate heat exchangers can be used for a wide range of material processings, from common civil use, industry used water to high viscosity fluid; from applications demanding high level of hygiene to chemical medium with high degree corrosion ; from clean liquid to fiber containing liquid. It has been widely used in petroleum, chemical industry, metallurgy, mining, electricity, nuclear power, central heating, shipping, pharmacy, food, chemical fiber, textile industry, paper making and so on.

THT removable plate heat exchanger mainly includes: special plate heat exchanger for centralized heating, special plate heat exchanger for nuclear power, marine plate heat exchanger, HVACR plate heat exchangers, special plate heat exchangers for beverage industry ,special plate heat exchangers for metallurgy ,special heat exchangers for petrochemicals ,wide gap plate heat exchangers.

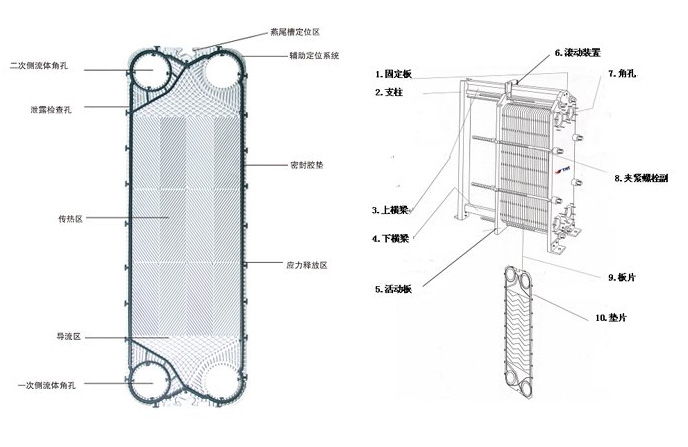

structure principle

| No. | Part name | Function of the parts |

| 1 | Frame plate | It is not in direct contact with the fluid, it is used to press and seal the plate pack with tightening bolts, and the inlet and outlet connections are fixed onto it. |

| 2 | Support column | Support the weight of the heat exchanger and integrate the whole heat exchanger together. |

| 3、4 | Caring & guiding bar | Support the weight of the heat exchanger and guarantee assembly size,the plates are suspended from caring bar that provides exact positioning of the plates and they can slid between the two bars, they usually are longer than the clamped plate pack so that allows to assembly, check and clean the plates when plate pack is unclamped. |

| 5 | Pressure plate | Pair with fixed frame plate slides freely on the caring bar in order to facilitate assembly and disassembly the palate pack. |

| 6 | Roller | Roller on pressure plate to allow easy opening and closing. |

| 7 | Port holes | Through port holes fluid can enter into the passages between the heat transfer plates. |

| 8 | Tightening bolts | To clamp the plate pack and ensure sealing effect meanwhle can also bear the pressure load. |

| 9 | plate | It is the heat transfer element, provides the area for medium flows through and heat transfer. |

| 10 | gasket | To prevent leakage and distribute fluids among different plates. |

| 11 | Intermediate bulkhead | Seting up intermediate bulkhead in the different positions between the frame plate and pressure plate can process multiple mediums and perform multiple operations on the same heat exchanger. |