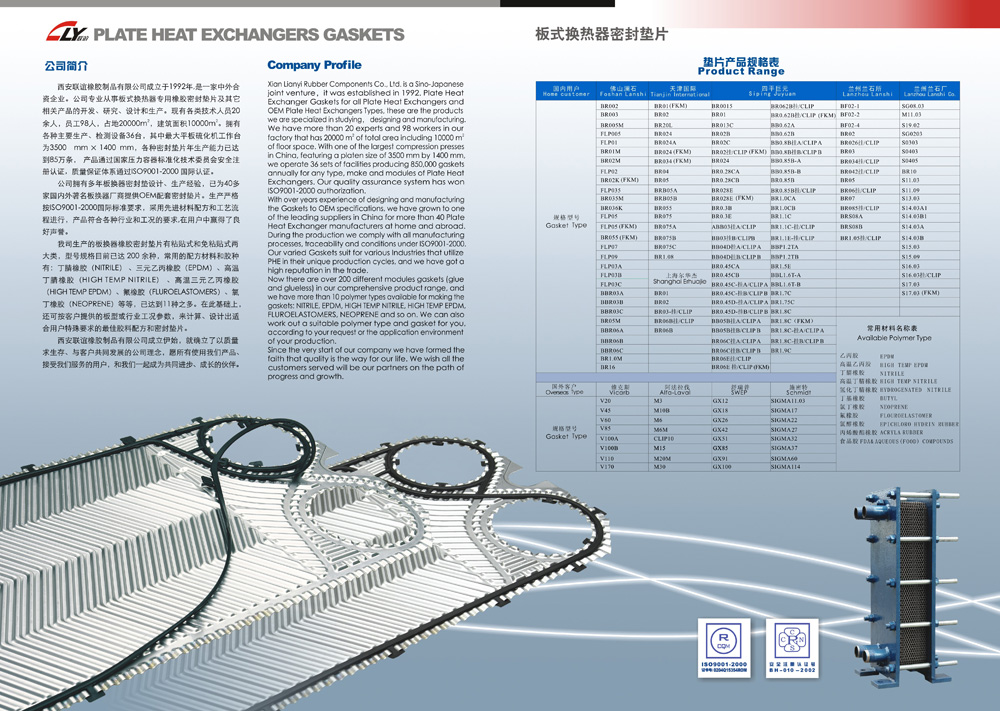

LIANYI PHE Gaskets

LIANYI PHE Gaskets

LIANYI PHE Gaskets

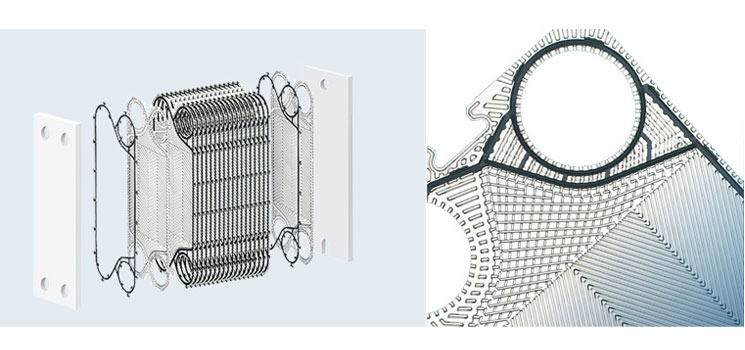

Lianyi PHE Gaskets are manufactured from different rubber compound that have been specially developed by Lianyi’s national leveled senior experts according to the different applications and environments of various Industries that utilize PHE in their unique production cycles.

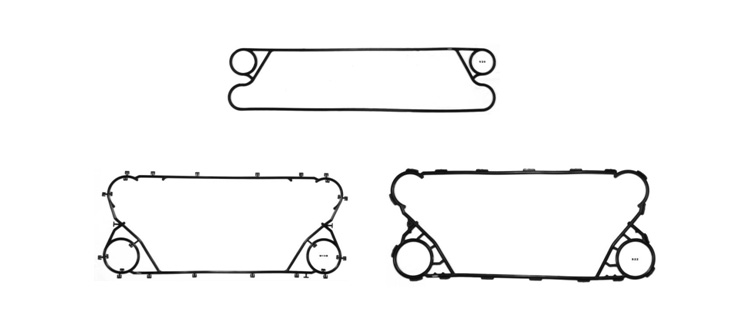

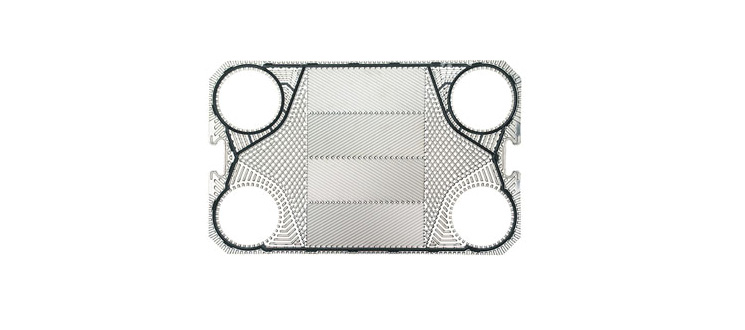

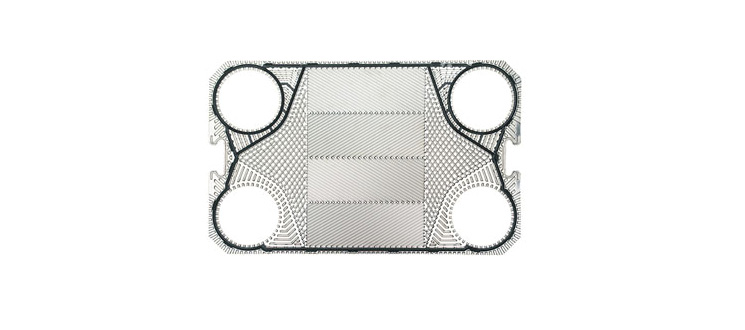

In accordance with assembling form PHE gaskets fall into two large categories, the Glued Fastening Type and Glue Free Fastening Type.

Glued Fastening Type Gasket:

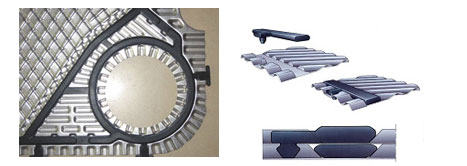

1. Clip-on

There are strong rubber buttons along the gasket edge, press the buttons into the relevant holes in the plate, then the gasket is snapped on. The gasket structure is slightly more complicated than a glue fastening type but it is easy to remove and re-gasket.

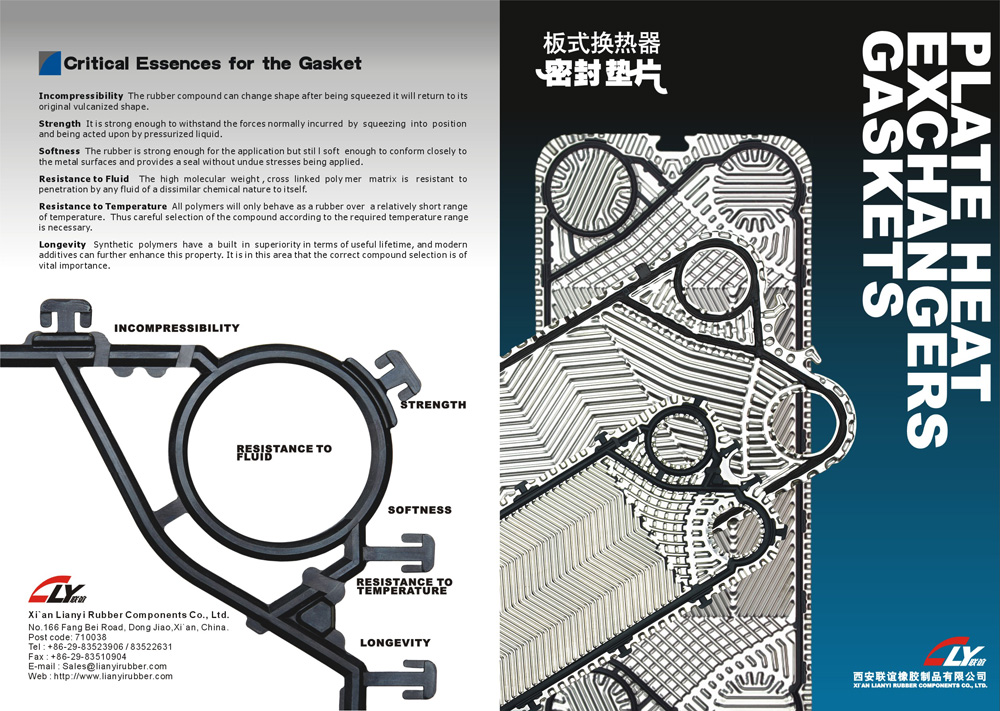

Critical Essences for the Gasket

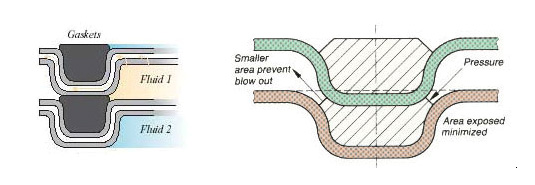

Incompressibility

The rubber compound can change shape, so that after being squeezed it will return to its original vulcanized shape.

Strength

It is strong enough to withstand the forces normally incurred by squeezing into position and being acted upon by pressurized liquid.

Softness

This is adjusted by compounding so that the rubber is strong enough for the application but still soft enough to conform closely to the metal surfaces and provides a seal without undue stresses being applied.

Resistance to Fluid

The high molecular weigh, cross linked polymer matrix is resistant to penetration by any fluid of a dissimilar chemical nature to itself.

Resistance to Temperature

All polymers will only behave as a rubber over a relatively short range of temperature. Thus careful selection of the compound according to the required temperature range is vital.

Longevity

Synthetic polymers have a built in superiority in terms of useful lifetime, and modern additives can further enhance this property. It is in this area that the correct compound selection is of vital importance.

Package :

Packing size :

520 X 325 X 260mm / 1100×800×740mm / or as request

Packaging quantity:

According to different product specifications and different customer requirements

Gasket-materials and Properties

Of all the component part materials, rubber is the least understood. Unlike metals and plastics, rubber does not have universal cut-and-dried design criteria. Choosing the right rubber material gasket for your PHE application can be a nightmare.

● The choice of rubber materials depends on

- Fluids – chemical attack or not

-The combination of temperature and pressure

● Rubber materials change properties due to

-Time – the rubber relaxes (stress relaxation)

-Temperature – the rubber deteriorates

- Hardening by attack of oxidizing agents(e.g., oxygen in air)

-Swelling or softening by absorption chemicals in the fluids

● Common gasket polymers

- Nitrile

- EPDM

- FKM

● Nitrile (NBR)

- Standard material up to 130℃

- NBR HT (performance) up to 140℃

- NBR B (base) for lower temperature

● Application related NBR qualities

- NBR (FDA food grade) - All the ingredients and amounts in the compound formula are accepted by the FDA and do meet the requirements of FDA list of Substances and Limitations.

- NBR LT - for low temperature in refrigeration applications

- HNBR (hydrogenated) for duties where normal NBR swells and for higher termperatures

● EPDM

- Standard material up to 160℃

- Standard EPDM qualities

- EPDM for glued gaskets (crushing resistant)

- EPDMC for clip-on gaskets at high temperature

- EPDMCT as above but for thing gaskets in models with low pressing depth (1.5 – 3 mm)

- Application related EPDM qualities

- EPDM (FDA food grade) –All the ingredients and amounts in the compound formula are accepted by the FDA and do meet the requirements of FDA list of Substances and Limitations.

- EPDM AL for increased pressure resistance in certain chemical duties where normal EPDM swells