Since its establishment, THT has been committed to strengthening heat transfer research and the development of advanced heat transfer elements, a large number of experimental data and operational experience have been accumulated for gas to gas heat transfer without phase change, liquid to liquid heat transfer, evaporation and condensation heat transfer with phase change. In the past 30 years, THT has successfully developed seven product groups suitable for various medium and low pressure conditions, more than 100 kinds of high efficiency heat exchange products. Especially at different flow rates, the research on heat transfer performance and resistance characteristics of various heat exchangers has been at the leading level in China, among them, THT plate evaporator and plate condenser have reached the international advanced level. THT is the national standard preparation unit of plate heat exchanger.

THT has been researching and developing intelligentization since the late 1980s, especially in the integration and intelligence of fluid systems. On our own, THT developed respectively for central heating system, intelligent water supply system, hot air circulating system, integrated evaporating station and intelligent heat pump system, and formed the unique style and mode of THT. From the central control system to the intelligent heat exchange station has reached the leading level in China. THT is the national standard establishment unit for GB/ t29466-2012 of plate heat exchanger unit.

Waste heat refers to the heat energy generated in the process of industrial production, which is not utilized and discharged. It is secondary energy carried in solid, liquid and gas medium such as slag, waste water, circulating water, spent steam and smoke. Middle and high temperature waste heat recovery technology is relatively simple and widely used, but low grade waste heat with low temperature has huge recover space, but it is difficult to recovery. Together with Tsinghua university and Xi’an Jiaotong university, THT has carried out the research and development of waste heat recovery technology and mature waste heat recovery and utilization integrated system can recover and comprehensively utilize these low-grade waste heat. At present, it has been applied to flue gas recovery and treatment, and gradient utilization of geothermal water, waste heat utilization of industrial and civil sewage, heat recovery and utilization of industrial circulating cooling water, heat recovery and utilization of industrial waste water, combined heat supply and capacity expansion and other fields.

The integrated platform of intelligent management and control of heat network manages equipment operation and maintenance through wired or wireless network., Real-time monitoring of heat source, real-time monitoring of heat network, network balance, operation decision analysis, GIS geographic information system, patrol inspection management, alarm and early warning and other aspects guide heating management from routine management to fine closed-loop management. In the fierce market competition environment, continue to improve the profit of heating enterprises.

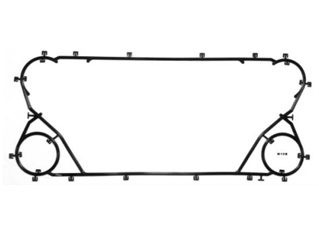

Lianyi Rubber has more than 20 years of experience as a major manufacturer of high-performance PHE gaskets for all plate heat exchangers.

Our mission is to make a critical and effective contribution to the efficiency, performance and reliability for our customers' PHE Sealing.

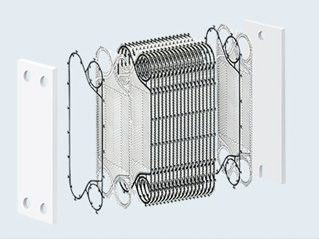

GUphe can provide customers with PHE complete set of assembly parts and undertake OEM, ODM and processing with supplied drawings business.